Overview

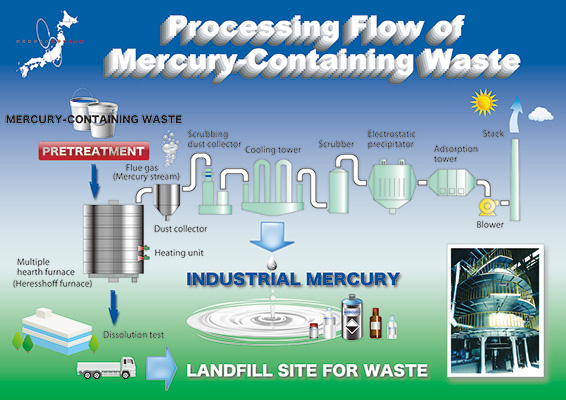

At Nomura Kohsan, we treat mercury-containing and mercury-contaminated waste through a roasting process. Our plant is equipped with two types of furnaces: the Herreshoff furnace (multiple-hearth furnace) and the rotary kiln. The use of each furnace depends on the concentration of mercury. Waste is heated at a temperature of around 600℃ to 800℃ in order to evaporate the mercury. The evaporated mercury would then flow into the exhaust gas channel and would be collected in the scrubber and cooling tower. In order to prevent the remaining mercury from discharging into the atmosphere, the plant is equipped with a mercury absorber at the final stage of the process.

In Japan, Air pollution control Act was amended from April 2018, and started the air regulation. Nomura Kohsan has already voluntarily set our standard to regulate mercury emission before Air pollution control Act was amended.

Once the hazardous substances have been eliminated through the roasting process, the greater portion of the materials left after the roasting process is recycled. A small portion of non-hazardous residue that cannot be recycled is stored in our on-site final landfill. The landfill is a double-layered, water-sealing reinforced concrete structure, which provides the utmost security and safety for the environment.